11 Mar The Wall Street Journal : How China Is Churning Out EVs Faster Than Everyone Else

Media Source : The Wall Street Journal

Once laggards, Chinese carmakers are stirring envy—and fear—in the global auto industry

By Selina Cheng in Hong Kong and Yoko Kubota in Beijing

Mar 4, 2024

China is speeding ahead in the electric-vehicle race. Riding the nation’s EV boom, upstart automakers have eclipsed foreign rivals to develop cars faster, push the boundaries of smart tech and swamp consumers with choice.

Chinese automakers are around 30% quicker in development than legacy manufacturers, industry executives say, largely because they have upended global practices built around decades of making complex combustion-engine cars. They work on many stages of development at once. They are willing to substitute traditional suppliers for smaller, faster ones. They run more virtual tests instead of time- consuming mechanical ones. And they are redefining when a car is ready to sell on the market.

Foreign carmakers openly admit they are chasing the game, increasingly wary of Chinese rivals they once considered also-rans. China’s prowess, combined with its global ambitions, is also stoking fears it could flood the world with cheap cars as demand for EVs slows.

NIO, one of China’s leading, though cash-burning, electric-vehicle startups, takes less than 36 months from the start of a project to delivery to customers, compared with roughly four years for many traditional carmakers. One reason: It puts out cars with latent technology such as a spare chip that allows it to frequently add new features through software updates.

“The faster you can introduce a new technology to the market, provided that it’s a reliable technology, then the chance for you to gain market share will be much bigger,” said Mark Zhou, the head of NIO’s product committee.

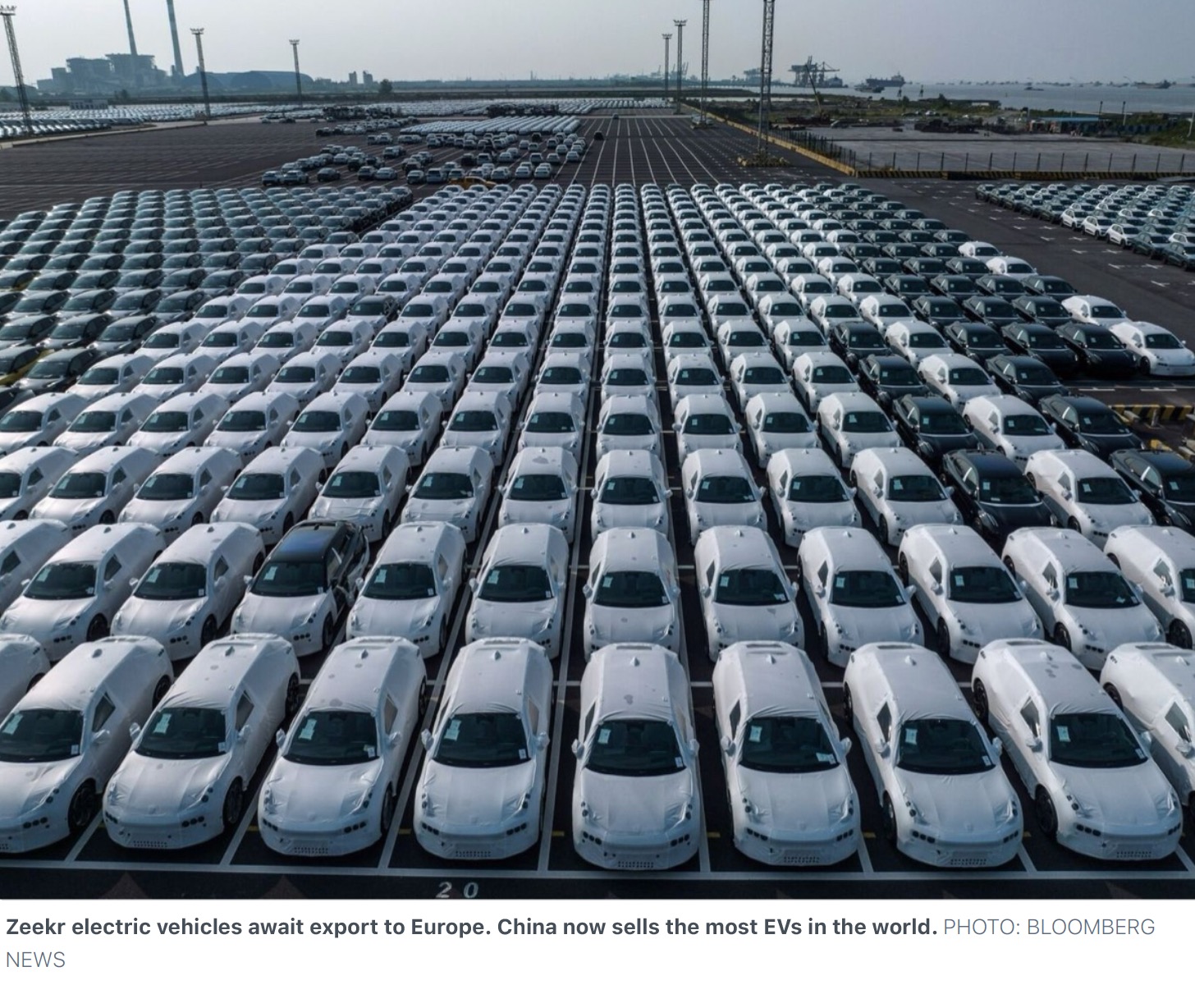

Zeekr, an EV venture from decades-old auto giant Geely, can develop vehicles from scratch in as fast as 24 months. It rapidly releases different models ranging from SUVs, multipurpose vehicles, and hatchbacks that all share manufacturing and digital architecture with other Geely brands such as Polestar and Smart.

Backed by generous government stimulus policies, China now sells the most EVs in the world. Its carmakers are heavily customer focused, emphasizing software and digital technology, from driver- assistance functions to in-car entertainment.

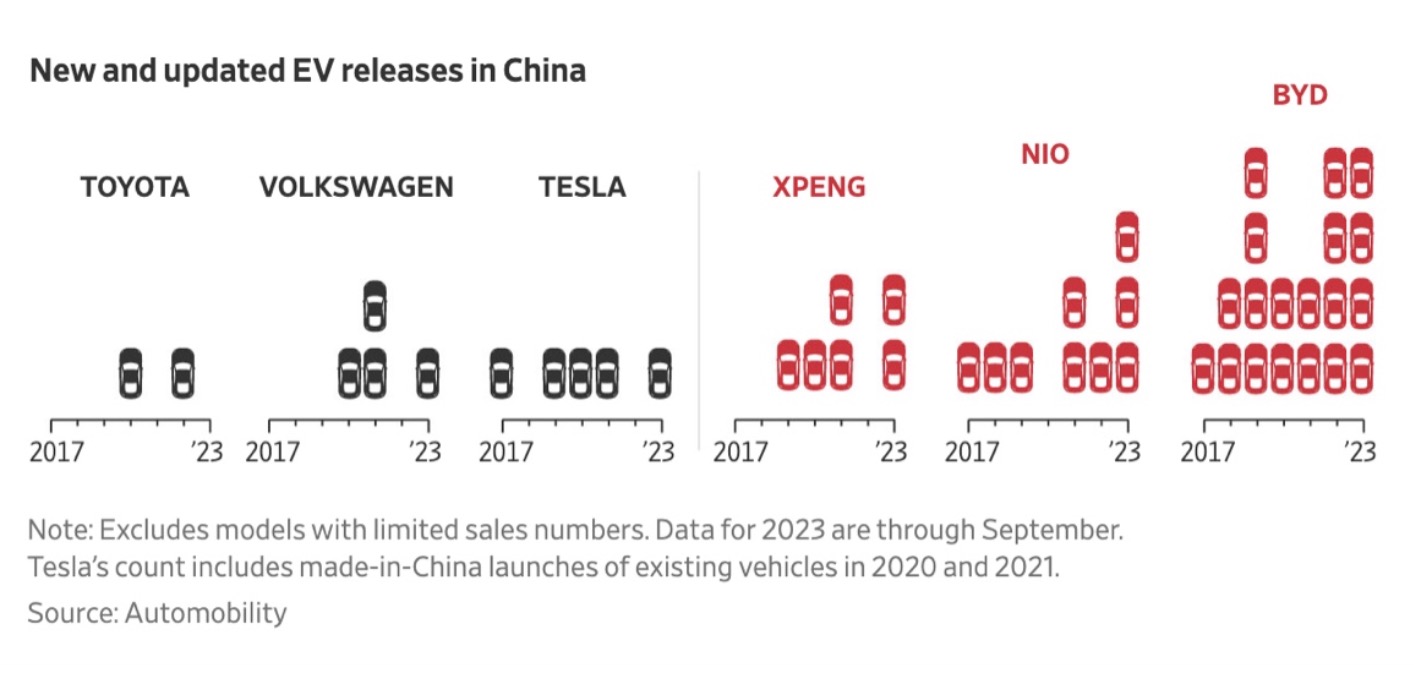

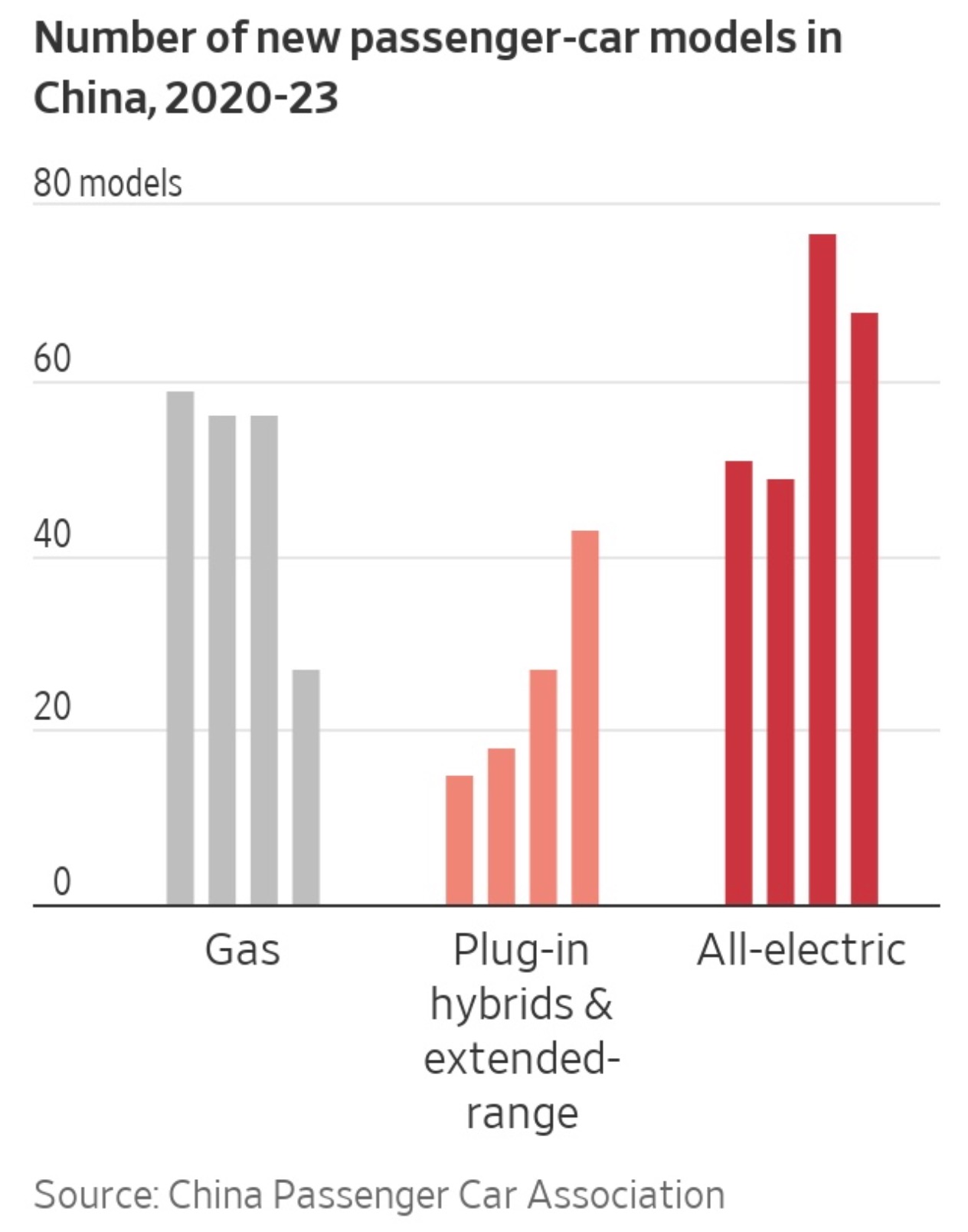

The slowdown in demand for EVs—even in China—is spurring Chinese carmakers to constantly update and release new models. Cars launched last year contributed to 90% of China’s passenger-car sales growth, according to the country’s passenger-car association.

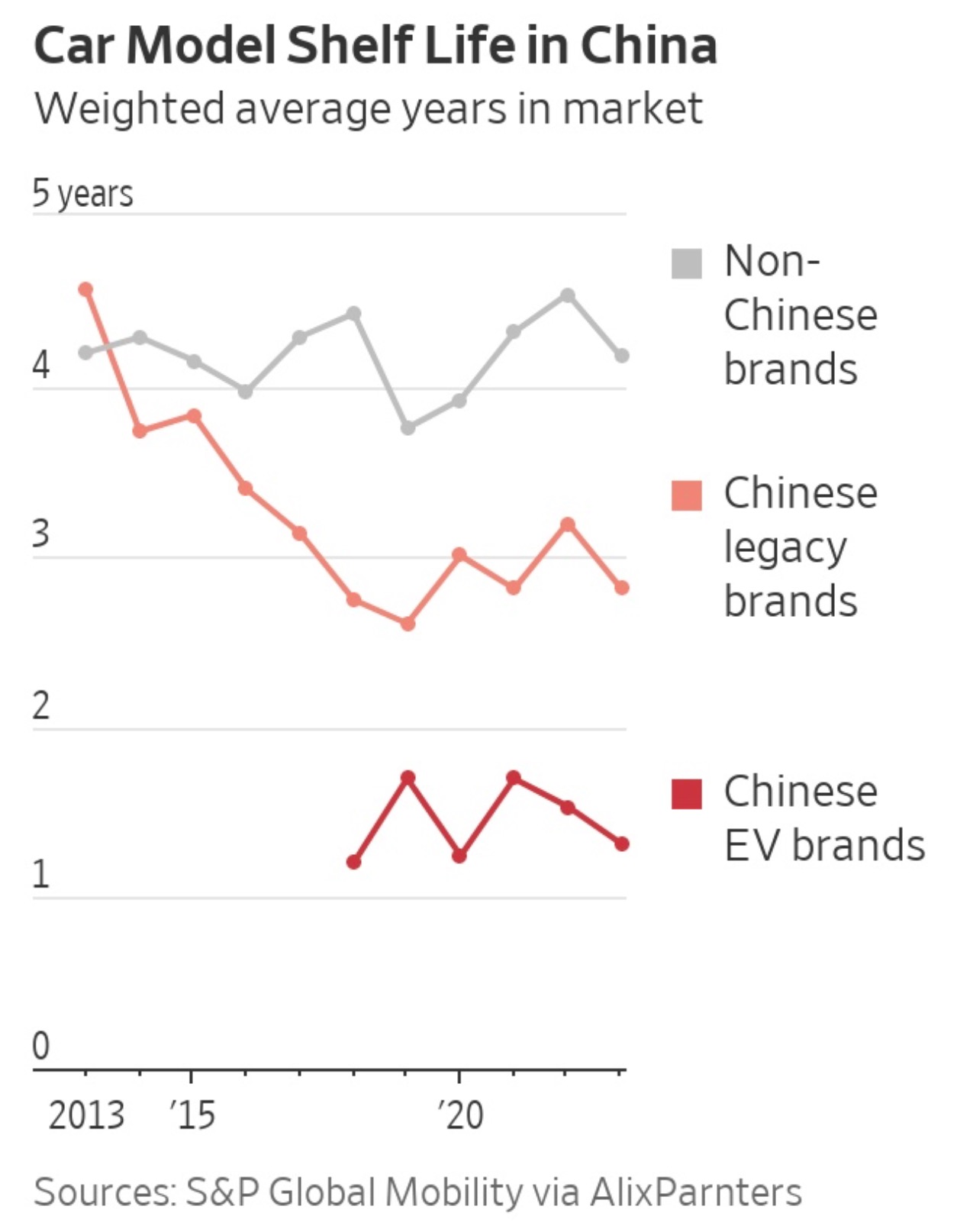

Because Chinese buyers tend to prefer new or recently released cars, the cars have a short shelf life. Domestic EV makers offer models for sale for an average of 1.3 years before they are updated or refreshed, compared with 4.2 years for foreign brands, according to an analysis by consulting firm AlixPartners.

In a reversal of industry convention, many global carmakers are now looking to learn from Chinese rivals. Tesla’s Elon Musk and Ford chief executive Jim Farley have both said their biggest future threats will be Chinese. Volkswagen and Nissan are adopting some Chinese ways to be speedier.

Global automakers risk falling behind in the technology if they scale back investments as Chinese rivals ramp up. Apple has scrapped its EV project and Tesla’s Elon Musk said the company will ship its updated Roadster starting next year, after years of delay. The share of EVs among global car sales is expected to reach as high as 40% by 2027 despite the recent slowdown.

Volkswagen is now partnering with Chinese companies as it looks to speed up its processes. Its China business head noted it took the company nearly four years to get a new product to the market, compared with little more than 2½ years for local manufacturers.

Global carmakers including Ford and Nissan are now moving to use their China factories to make cars for export around the world. China surpassed Japan as the world’s top auto exporter last year.

Concerns about China-made cars are increasing. On Thursday, the Biden administration said it would investigate foreign car technologies, citing potential national security risks from China. The European Union is conducting an antisubsidy probe into China’s EV makers.

Not all of the ways China is moving ahead are innovations. Automakers in the country are adopting and pushing forward ideas from Tesla, such as focusing on upgrading car features through software updates. Tesla has been ousted as the world’s top EV seller by China’s BYD.

China’s EV boom is so recent that it remains to be seen whether there are any trade-offs between faster development and vehicle safety and quality. Chinese carmakers insist they make no compromises, but some in the industry say their focus is on seeking growth first, whereas legacy carmakers foster a robust system around meeting safety and quality standards.

Everything all at once

As Chinese carmakers have moved to produce software-driven smart EVs, many development steps are taken in parallel, executives say. Traditionally, making gas-powered cars was a linear process—from design to engineering to manufacturing, each step had to be completed and validated before the next.

Chinese EV companies heavily use simulation software to create virtual prototypes and run tests in more iterations and in faster time. Virtual parts and mock-ups can be worked on between teams and 3D printed prototypes allow engineers to go through loops of trial and error much quicker, executives at Zeekr and NIO said.

There is no need to wait for hardware parts to be completed to develop assisted driving and powertrain control software, said Zhu Ling, a vice president of Zeekr.

JiYue, an EV brand created by Geely and Chinese tech giant Baidu, can finish product design in six months, said CEO Joe Xia. He visits the design studio almost every week, bringing employees from sales, marketing, manufacturing, product development and software. Any design feature changes can be understood by all so they can make relevant changes, he said.

German and Japanese carmakers have well-defined standards and guidelines for every step in car manufacturing and development, but these are barriers to moving quickly, said Christoph Weber, the China general manager for AutoForm, a Swiss company that makes simulation software for car manufacturing.

Make now, update later

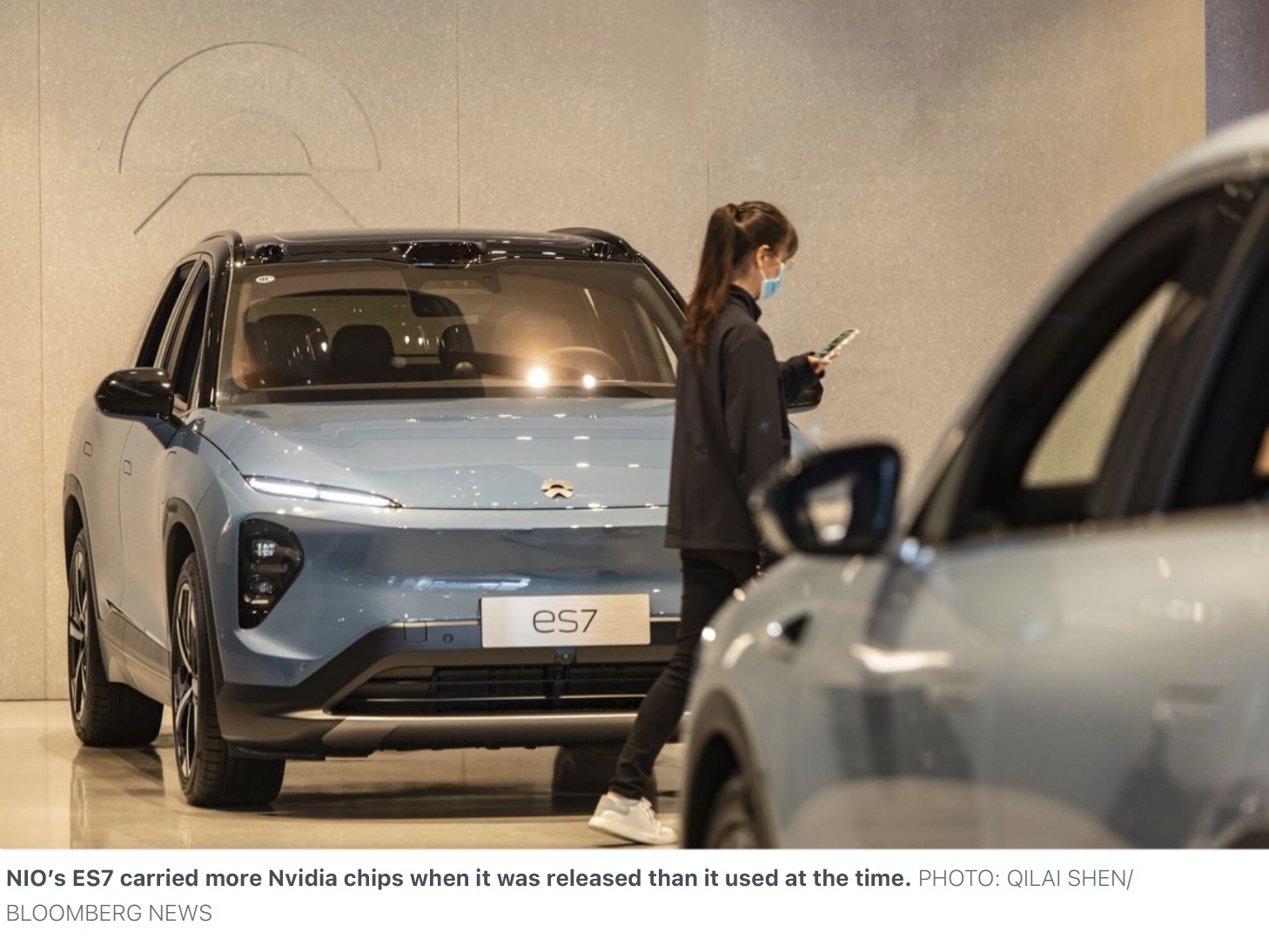

NIO, the EV-maker that was once dubbed China’s Tesla killer, has changed when a car is deemed ready for market. It classifies its releases as “minimum viable products.” That means they have more advanced chips, cameras or sensors than its software can support at the time. Engineers continue to develop tech and later send over-the-air updates to drivers that exploit unused capabilities.

NIO’s ES7 SUV carried four Nvidia Orin chips when it was released in June 2022, but only three were in use. The fourth chip was activated last year to boost computing speed, so a traffic light signal appears on the car screen with a real-time countdown. Another update means the car sends a notification when a traffic signal turns green. NIO’s next update will allow the vehicle to automatically start or stop the car depending on the traffic signal.

“If the minimum viable product will allow us to take the lead over other competitors, that’s attractive enough for our users,” Zhou said.

NIO is churning out new models even as its losses mount and the company laid off 10% of its staff late last year.

Speedy suppliers

Global carmakers typically won’t approve new suppliers without a lengthy vetting process, industry executives say. Chinese ones will rope suppliers in early when conceiving a car to avoid back and forth later.

In the case of BYD, delivery time from a Japanese mold supplier has been cut to around six months from at least a year since it bought the company more than a decade ago. BYD did so by involving experts from the supplier to advise on molding from the early stage and set its design earlier in the development process.

When Zeekr was designing the Zeekr X, a premium hatchback crossover with an in-car fridge to keep drinks cool, it first sourced the appliance from a well-known manufacturer. But the supplier’s quote was too expensive and delivery would be too slow, said Zhu. The company picked a smaller manufacturer that specializes in outdoor fridges and was able to deliver within a year instead of two.

“In the age of EVs, whether your car is launched six months earlier or later, the market condition is totally different,” Zhu said.

One size fits all

China’s carmakers are increasingly standardizing their models to cut time. Beyond traditional mechanical platforms, they standardize everything from important software to the digital vehicle operating systems that executives liken to the nerve center of smartcars.

EV startup XPeng last year introduced the SEPA2.0 that combines features including the operating system, driver-assistance software and battery pack design for use across all models. XPeng says it shortens research-and-development cycles by around 20%.

Figuring out software on cars and making them gel well with hardware is one area where traditional carmakers such as Volkswagen and Toyota have struggled.

XPeng’s approach is in part possible because the carmaker develops software in-house alongside vehicle hardware, said Brian Gu, the carmaker’s co-president. For global carmakers, the software-development job was traditionally done by external suppliers. Volkswagen last year obtained a stake in XPeng to partner in vehicle development and technology.

Startup spirit

Many Chinese EV makers operate more like startups than legacy automakers. They have a smaller number of employees who say they tend to work longer hours. Executives are more willing to override standard processes to push new products to the market sooner, experts in the industry say, even if it could be harder to fence in risks and costs when things go wrong.

At NIO, the next model’s design emerges from various pitches sent in by its car designers based in Munich and in China. CEO William Li attends weekly design meetings with the help of identical clay mock-ups in both countries and calls the shots on the final design for all future models. This is different from many Western carmakers, where design options are sent through different departments for review, a much lengthier process, said NIO’s design chief Kris Tomasson, who previously worked with Ford and BMW.

Write to Selina Cheng at selina.cheng@wsj.com and Yoko Kubota at y[email protected]

Source : The Wall Street Journal

Sorry, the comment form is closed at this time.